Select category:

We have been the leading manufacturer of funeral equipment in the region for 60 years.

We procure raw materials from the domestic market and use 2 types of wood material carrying the authenticity of our region.

Poplar

Poplar is a very durable wood, and at the same time a light material. It does not contain resin, it is easy to process, and is therefore ideal for manual processing. Poplar has a smooth surface easy to paint. All the products known for their high gloss and hand-made decorations are made from poplar.

Historical records say that the headquarters of our factory in Bačka Topola got its name in the 16th century because a very large number of white poplars grew on its territory. This is the reason the poplar has a historical and emotional value, which only our company can provide to its customers.

Oak

Oak has quite a long growing period. This is the reason this noble tree has a great value. By the nature of the material, oak has a higher weight than other types of wood. We do not paint this product, but only stain it, to emphasize and keep its natural patterns, the way nature created them. We produce the most exclusive products from oak wood. Some of these models are the products in high demand abroad, with which we have positioned the "Usluge" brand on the international market.

Technology

During our 60-year tradition, we have continuously modernized the technology we use in the production process. At the same time, we have preserved the authenticity of our finished products, which are still recognizable today by handmade parts. We produce over 15 000 coffins a year, which we then transport to various parts of our country, as well as abroad.

From nature to the finished product

For generations , Our employees have been passing down their knowledge to the younger generation. We nurture a tradition of love for creation and for nature. We constantly expand the competencies of our employees and improve their skills. It is important to us that each of them contributes to the quality of our product range. Our employees know all the stages in production, from the log to the finished product.

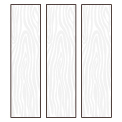

1. Boards

Delimbing and cutting out logs,

drying boards,

sorting by quality,

joining into plate material,

cutting out boards,

shaping,

four-sided blasting.

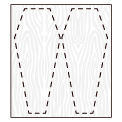

2. Panels

Profiling of boards,

milling,

bottom cutting,

longitudinal connection,

final levelling,

thickening of elements,

profiling elements,

cutting to measure.

3. Assembling

Plugging,

making a pack,

plastering,

grinding,

assembling,

final plastering and grinding,

mounting the pack.

4. Making

CNC cutting out,

carving,

final plastering and sanding,

assembling the coffin,

smoothing and grinding corners,

decorating.

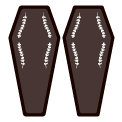

5. Finalization

Applying the base,

varnishing,

mounting handles,

upholstery,

packaging,

storage,

transport.

6. Support

Planning,

organization,

commercial department,

complaints,

marketing,

finance department,

statistics,

personnel.